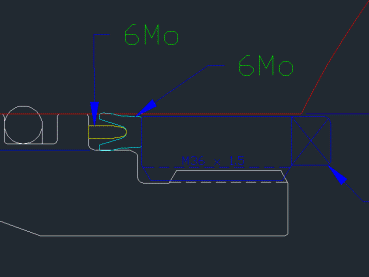

Metal to Metal Seals

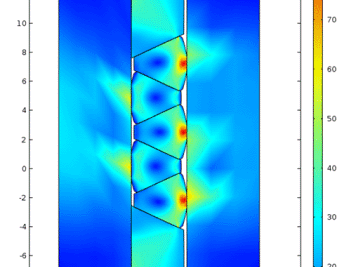

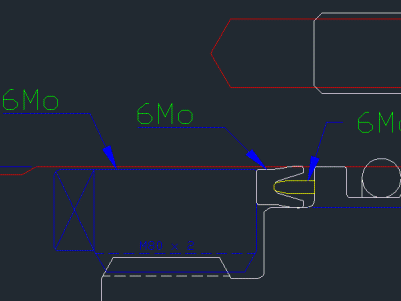

- Super compact designs (~3 x 3mm cross-section envelope)

- Bubble-free static & low-bubble dynamic

- High & low pressure / 5 bar – 1000+ bar; and vacuum

- High & low temperature / -30 – 170+ ⁰C

- Corrosive environments – H2S, CO2, Sea Water

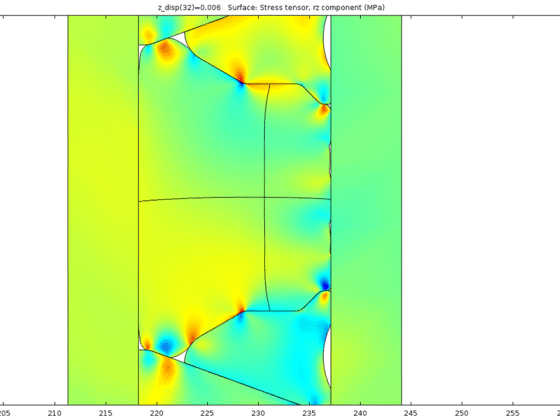

We minimise the loosest-fit contact pressure in our seals to the lowest level that seals well. This enables more install/removal cycles & reduced wear rates. We also aim for very compact designs that are not overly pressure energised. Our durable seals last longer, suffer less from cold-welding (galling) problems and cost less to manufacture.

Polymer Seals

- Typically using PEEK, PTFE & HNBR Materials

- High & low pressure / 5 bar – 1000+ bar

- High & low temperature / -20 – 150+ ⁰C

- Static, dynamic and pressure blow-down applications (sudden vent down)

- Expanding designs; where seal runs below flush and is later energised by axial squeeze)

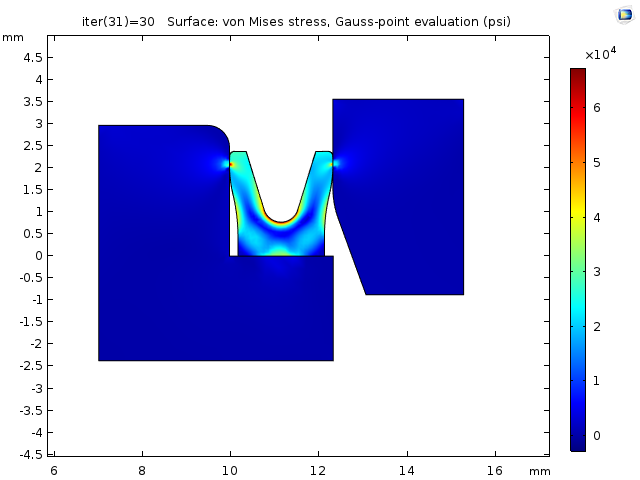

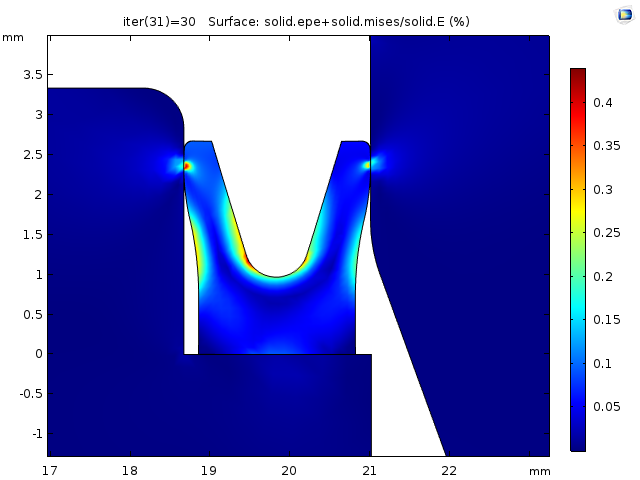

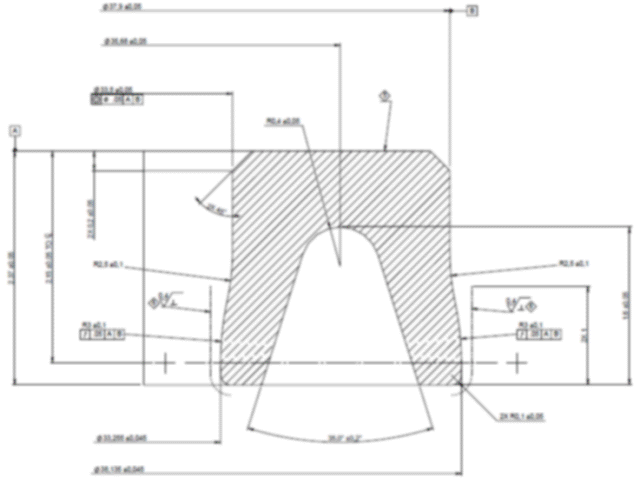

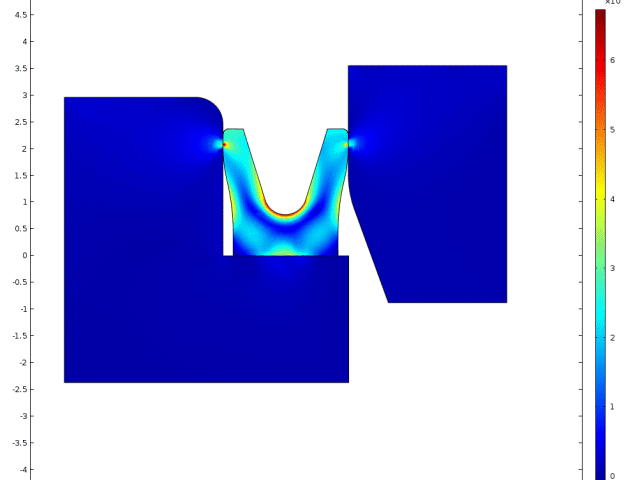

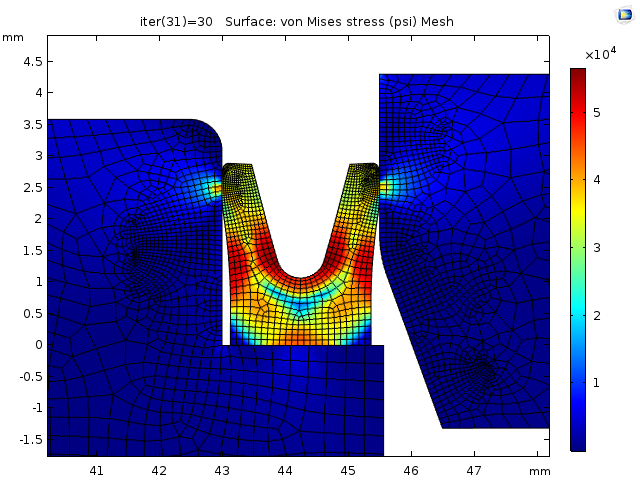

We usually get involved in Polymer seal engineering where regular seal suppliers can’t get their seals to work successfully. Our seals are designed from scratch to each application. We use FEA, as well as building on previous successful designs. Some of our seal designs are installed currently in Oil & Gas applications on Norwegian Continental Shelf region. We work closely with some seal manufacturers to ensure that our seal designs can be reliably manufactured.

We are also happy to take on demanding applications such as those involving rapid pressure blow-down, for example where a seal exits its seal bore and pressure then vents rapidly past the seal. Typically in these sort of applications we will combine Polymer seal elements with metal flow-choke elements.